As outdoor metal surfaces age, they are exposed to the elements and start to corrode. The most common type of corrosion seen on galvanized steel is zinc rust. This post will discuss why this occurs, what types of metal coatings are available for protecting galvanized steel from corrosion and which type you may want to choose for your application.

How does zinc prevent rusting?

Zinc is a metal that can be surprisingly resistant to rusting. This may sound counterintuitive since zinc oxide (the most common form of corrosion) is white and the most visible sign of oxidation on galvanized steel surfaces. What many people don’t know about this phenomenon is that it happens because zinc has an affinity for water molecules, which means they are more likely to stick around than with other metals like iron or aluminum. When they do come in contact with air, these water molecules react together and create a protective layer called hydroxyls on the surface of the metal.

CRC 05048 Zinc-It Instant Cold Galvanize

Zinc-It Instant Cold Galvanize is the fastest drying, highest performance zinc coating available. It dries to a flat gray finish in less than 5 minutes and provides active rust protection for up to 6 months. Zinc-It’s advanced formula is an excellent alternative to hot-dip galvanization that provides on-the-job convenience without sacrificing quality or durability.

- Dries fast.

- High-Performance coating of >93% pure zinc. Actively fights rust and corrosion. Leaves a flat gray paintable finish on surfaces.

How fast does zinc rust?

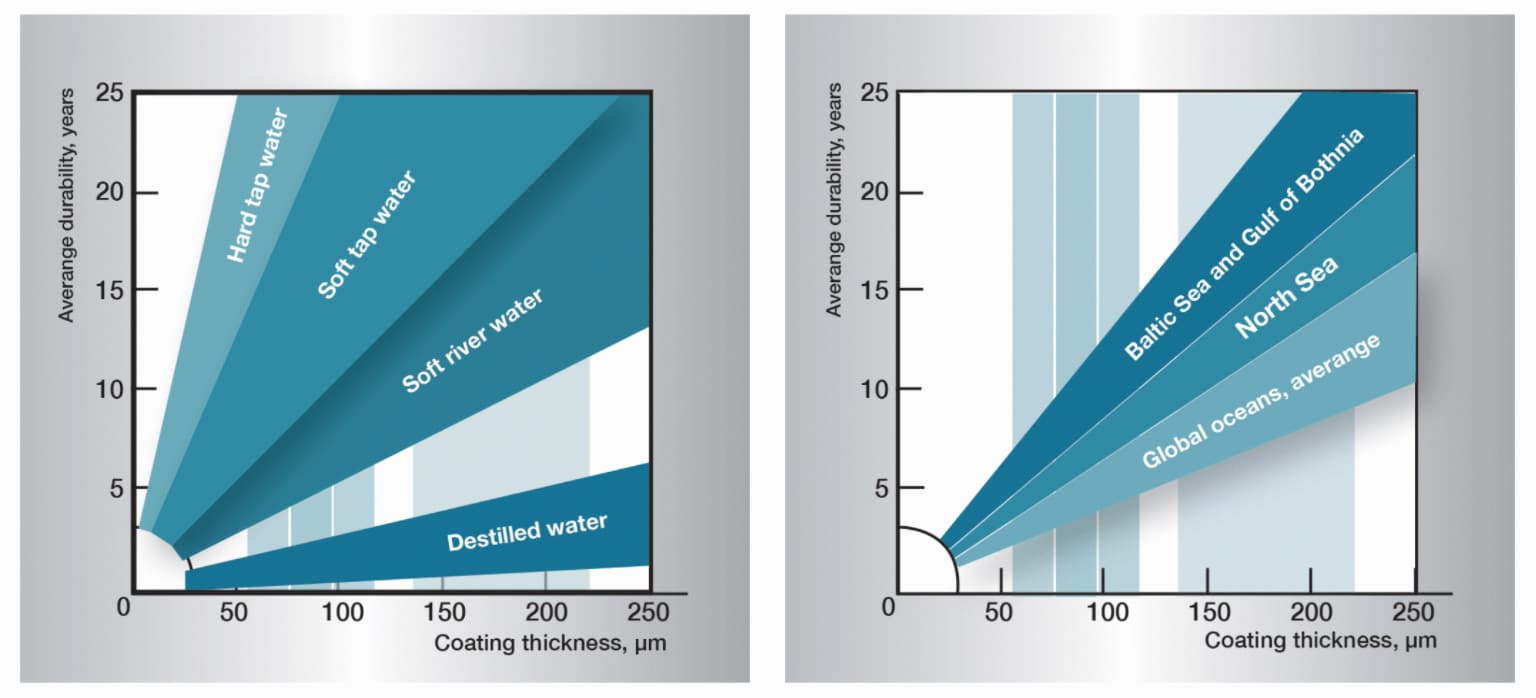

It depends on the environment and the type of coating. Zinc is more resistant to rusting in a marine atmosphere because it’s less humid, whereas additional humidity can speed up corrosion rates on galvanized steel.

Because zinc has an affinity for water molecules, hydrated zinc (zinc that has been contaminated by exposure to moisture) forms faster than dry oxide, though this process takes typically 18 months or so in most cases before there are noticeable signs of deterioration visible through visual inspection alone.

There are many different types of coatings available today with varying levels of effectiveness against oxidation and other factors like temperature change. Electroless nickel plating is probably one of the best choices.

Does zinc rust in saltwater or air?

Saltwater is an aggressive and corrosive environment that presents a high risk of corrosion to unprotected steel.

Zinc is not resistant to saltwater environments, so the zinc coating will corrode over time and expose the underlying metal or substrate material.

Air corrosion occurs when moisture enters an area where it would normally be dry, such as in coastal regions with salty air. In this case, galvanized steel without protective coatings may experience surface rusting within just hours after being exposed to moist air for extended periods of time.

The most prevalent type of oxidation on exterior galvanized steel surfaces is crevice corrosion which typically starts near cracks or other sharp edges like rivets before spreading outwards from there.

Does zinc rust in concrete?

Zinc does not oxidize in concrete.

Does zinc rust in water?

Well, it depends on some factors such as the type of zinc, the pH level, and other factors.

Zinc does not typically rust in water unless it is exposed to high acidity or low alkalinity levels which can cause corrosion over time.

How does zinc coating prevent rusting?

As mentioned above, the galvanized layer of zinc is an excellent barrier against corrosion.

Zinc coating prevents rusting by creating a tough, protective outer shell that slows down oxidation and protects the steel from exposure to moisture.

Steel coated with zinc does not need any other type of metal plating or paint because it provides protection in all conditions for years.

In Conclusion

The answer to the question “does zinc rust” is yes, it does. However, unlike iron and steel which react with oxygen in the air to form a layer of oxide on their surface that helps protect them from further corrosion, zinc’s low reactivity means that oxidation doesn’t happen very quickly or fully. Zinc also reacts poorly with water so if you do find yourself in an emergency situation where your metal has come into contact with both water and air for some time then it’s best to remove it as soon as possible before any more damage can be done.

Leave a Reply