Rust is a serious problem in the automotive industry. Rust will eat away at metal and deteriorate it over time, so if you notice rust on your car, you need to take care of the problem quickly before it does any more damage. One way to get rid of rust is with fiberglass. This post will show you how to fix that pesky hole in your car’s bodywork using fiberglass!

What is fiberglass?

Fiberglass is the material that you can use to cover up a hole in your car’s bodywork. It can also be used as an inexpensive replacement for parts of the exterior or interior. Fiberglass is made by spinning and weaving fiber resin with strands of glass, creating a strong but lightweight solution. To make it into something useful such as fiberglass matting, layers are added together and baked until they harden like rock candy!

If you can take the part that needs to be repaired off, it will be easier for you.

Step 1. Cleaning the Metal of Rust

This can be done in several ways. You can use an angle grinder to grind away the rust. If your car has a lot of rust, this might work best for you.

In some instances, it will be easier if you have access to a sandblaster or high-pressure hose; these two tools are great at removing paint from metal and should do well on rust too!

Also you can use a wire brush to scrub away the rust, but it can be time consuming.

We believe that it would be most convenient to use a grinder with sander discs, so we recommend this method.

All you have to do is scrape the surface until all the rust is removed.

The reverse side should also be cleaned of rust, if possible.

Step 2. Applying the Rust Converter

You will need to apply the rust converter in a thick coat onto the metal. This is best done with an artists paintbrush or something similar.

You can even use your fingers if you don’t have anything else, but make sure they’re clean! Just repeat all the steps in the instructions and do not forget the protective equipment!

You need to make sure that the rust converter is applied in a thick coat because this will help it to last longer.

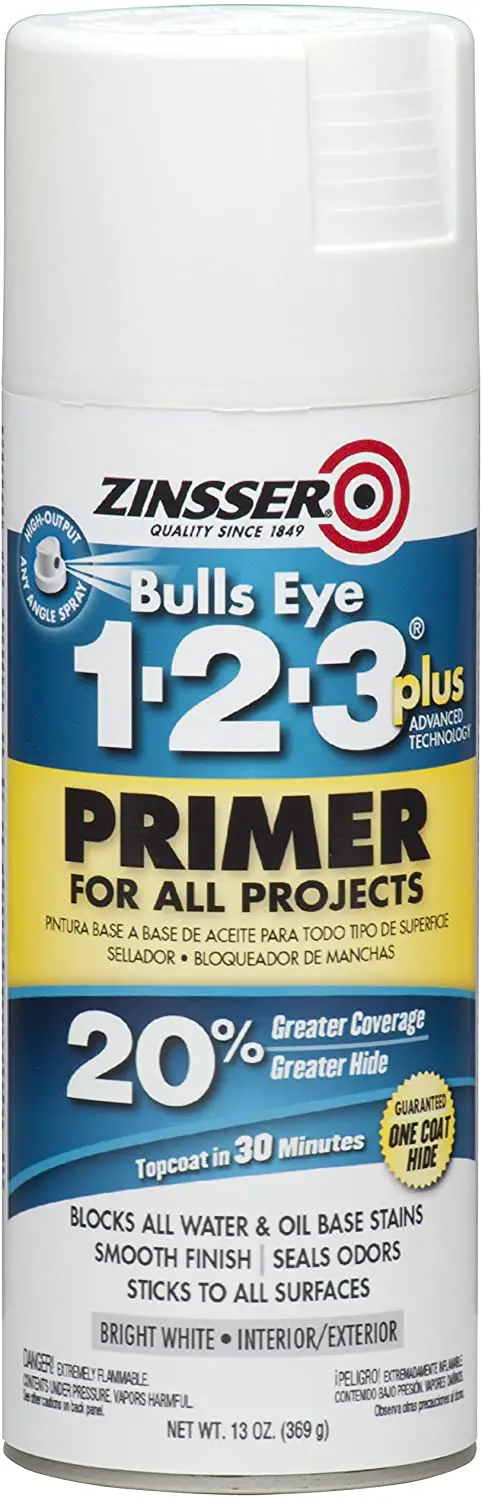

Step 3. Primer Application

Now you need to degrease the metal before applying the primer.

This can be done with a degreaser or white spirit. You want to clean off any dirt before you apply a coat of primer because this will act as your basecoat for the fiberglass, so it needs to be smooth and paintable!

After making sure that the surface is clean and dry you can apply prime onr the metal, just as you would do with a can of paint. This should take care of any remaining rust and give your fiberglass something to stick to!

Now before you start applying your first piece or matting make sure that all areas are free from dust and debris. The last thing you want is for anything to get caught up in there while it’s hardening so be careful!

After you put a few coats of primer you need to sand it a bit to make small scratches on which the polyester resin will cling. We recommend using 220 grit sandpaper or something like that.

Step 4. Fiberglass Aplication

Now you can apply sheets of fiberglass cloth to the surface of the metal in any way you like.

First we cut the fiberglass cloth into strips about an inch wide.

And then we applied them to the metal and taped them together like in the photo

This way we taped up the whole hole.

Step 5. Polyester Resin Application

Take the polyester resin and start diluting it with hardener as described in the instructions.

Turn the part upside down and with a brush liberally apply the polyester resin to the glass fabric.

Now add a few strips of fiberglass and on this side, and then also apply polyester resin to them.

Repeat this several times until 3-4 coats are applied and leave to dry for as long as specified in the instructions.

Step 6. Sweep

Now that it is dry, we can remove the tape from the surface.

In order to clean the rest of the fiberglass cloth, we will use a grinder as we did when we cleaned the rust from the part and do all the things we did in step 3.

Step 7. Aplying Putty

Using a putty knife, apply putty to the work area.

After it has dried, smooth everything out using 220 grit sandpaper and repeat all these steps until the surface is perfect.

And again we repeat the steps we performed in step 3

Step 8. Painting

The last step is to pain thet whole surface.

In order to find the right color you can get it from the dealer simply by telling him your vin number.

To apply the paint you may need a spray gun or you can apply it with a spray can. Follow the instructions and you will be fine. Don’t forget to wear protective equipment before painting.

Summary

In this article we told the reader how to fix rust holes on a car with fiberglass.

The material is divided into eight steps which are: scraping off rust, applying rust converter, priming surface and glassfiber matting, degreasing metal before applying primer, sanding polyester resin coating after it has dried for three or four times application of primer; removing tape from surface when drying process is complete; putting putty over work area and smoothing out using 220 grit sandpaper; painting whole surface with protective equipment like gloves an mask etc.; finding matching paint color at dealers by telling vin number.

It takes about two weeks in total if you follow these instructions meticulously.

Have you ever used fiberglass over roughed up metal that has been coated with POR 15 or a similar product?

I’ve found that if the underlying metal is roughed up, it will fill in the larger cracks of the embedded fibers and provide for better adhesion. I know POR 15 is a strong product on its own but we are talking about something that can be laid down and sanded smooth for painting after curing. Granted this won’t work on every substrate or all situations but I’ve had success using this method atop some more ‘difficult’ substrates.

I have rust holes in my floor pans the size of quarters. I’ve been considering either repairing or resurfacing them with POR 15 and laying fiberglass over it. As much as I want to repair the hole, I’m wondering if anyone has ever done this before so that they can offer me some advice about what kind of results to expect?

I’ve had holes in my floor pans repaired with POR15 and fiberglass. The holes were much smaller than quarters, but a lot of rust nonetheless. The whole process took me several weekends over a couple months. I removed as much of the rust as possible by wire brushing, then sandblasted all surfaces, including some metal pieces held on by rusted-on nuts. Be sure to remove the bolts from those pieces too before blasting so they don’t get lost. After cleaning all surfaces thoroughly with an acid wash (water and muriatic acid), rinse well with water and dry all surfaces. You can’t wire brush or sandblast through the paint, so it needs to be removed with a chemical process like acid wash first.