So, What Gauge Sheet Metal for Rust Repair? In repairing rust on a vehicle, choosing the right gauge sheet metal is crucial. Not only does the thickness of the metal impact the overall strength and durability of the repair, but it also affects the appearance of the repair once it’s completed. In this blog post, we’ll dive into the world of gauge sheet metal and discuss what to consider when choosing the right gauge for rust repair.

We’ll start by defining what gauge is, and how it’s used to measure the thickness of sheet metal. From there, we’ll look at the different gauges available, and the pros and cons of each. We’ll also discuss how the gauge of the metal can impact the overall outcome of the repair, and what to keep in mind when making your selection. Whether you’re a seasoned mechanic or just starting to explore the world of rust repair, this post will provide you with all the information you need to make an informed decision about what gauge sheet metal to use for your next project.

What Gauge Sheet Metal For Rust Repair: Personal Opinion

The gauge of the metal refers to its thickness, and selecting the right gauge can have a huge impact on the strength and durability of the repair, as well as its appearance.

There are different gauges available, each with its own pros and cons. Some gauges are thicker, making them more durable and suitable for areas of the vehicle that will see more wear and tear. Other gauges are thinner and better for areas that are less visible. It all depends on your individual needs and the specific repair you’re making.

In my opinion, a great option for rust repair is 20 gauge sheet metal. It’s not too thick, so it’s easy to work with, but it’s still strong enough to provide a solid repair. This gauge is also versatile, so it can be used in a variety of different situations. Another option to consider is 22 gauge sheet metal. This gauge is a bit thinner than 20 gauge, but it still provides good strength and durability.

Overall, choosing the right gauge sheet metal for rust repair is all about finding the right balance between strength, durability, and appearance. With a little bit of research and consideration, you’ll be able to find the perfect gauge for your specific needs. And trust me, making the right choice will make all the difference in the end result of your repair.

What Gauge Sheet Metal For Rust Repair Comparison Table

Introduction

When repairing rust on a vehicle, choosing the right gauge sheet metal is crucial. The thickness of the metal affects the overall strength and durability of the repair, as well as its appearance. In this guide, we’ll take a look at different methods for determining what gauge sheet metal to use for rust repair and compare the pros and cons of each.

Method 1: Consult a Professional

One of the easiest and most reliable methods for determining what gauge sheet metal to use for rust repair is to consult a professional. Mechanics and body shop technicians are trained in the art of rust repair, and they have the experience and knowledge needed to make an informed decision about what gauge sheet metal to use for each specific repair. If you’re unsure about what gauge sheet metal to use, consulting a professional is a great first step.

Pros:

- Expert advice and guidance

- No need to research or make decisions on your own

- Peace of mind knowing the repair is being handled by a professional

Cons:

- May require a fee for the professional’s services

- May not be as convenient if you’re trying to complete the repair on your own

Method 2: Research Online

Another option for determining what gauge sheet metal to use for rust repair is to research online. There are numerous websites and forums dedicated to automotive repair, and many of these resources provide information on what gauge sheet metal is best for different types of rust repair. You can also read reviews and product descriptions of different gauges of sheet metal to get a better idea of what to expect.

Pros:

- Convenient and accessible

- Can be done from the comfort of your own home

- No need to pay for professional services

Cons:

- Overwhelming amount of information available online

- May not be as reliable as information from a professional

- Difficulty in distinguishing between credible and non-credible sources

Method 3: Experiment with Different Gauges

Finally, another option for determining what gauge sheet metal to use for rust repair is to experiment with different gauges. If you have access to a variety of gauges of sheet metal, you can try out different gauges on a small scale and see how each one performs. This can be a great way to get a feel for what gauge sheet metal is best for your specific repair, and it can also be a lot of fun.

Pros:

- Hands-on learning experience

- Ability to get a feel for how different gauges perform

- Can be done at your own pace and on your own schedule

Cons:

- May be more time-consuming than other methods

- Can be more expensive if you need to purchase multiple gauges of sheet metal

- May not provide as reliable results as information from a professional or research online

| Method | Pros | Cons |

|---|---|---|

| Consult a Professional | Expert advice and guidance; No need to research or make decisions on your own; Peace of mind knowing the repair is being handled by a professional | May require a fee for the professional’s services; May not be as convenient if you’re trying to complete the repair on your own |

| Research Online | Convenient and accessible; Can be done from the comfort of your own home; No need to pay for professional services | Overwhelming amount of information available online; May not be as reliable as information from a professional; Difficulty in distinguishing between credible and non-credible sources |

| Experiment with Different Gauges | Hands-on learning experience; Ability to get a feel for how different gauges perform; Can be done at your own pace and on your own schedule | May be more time-consuming than other methods; Can be more expensive if you need |

Equipment To Work With What Gauge Sheet Metal For Rust Repair

| Equipment | Purpose | Additional Information |

|---|---|---|

| Sheet metal gauge tool | To determine the thickness of the sheet metal | Can be purchased online or at an automotive supply store |

| Metal cutting saw | To cut the sheet metal to the appropriate size | Can be a hacksaw, jigsaw, or metal cutting saw |

| Metal bending tool | To bend the sheet metal to fit the contours of the repair area | Can be a metal brake, sheet metal bending pliers, or a metal bending tool kit |

| Metal hole punch | To create holes in the sheet metal for screws or rivets | Can be a manual or hydraulic punch |

| Rivet gun | To attach the sheet metal to the vehicle using rivets | Can be pneumatic or manual, and should be compatible with the size of the rivets being used |

| Spot weld drill | To drill out spot welds to remove old sheet metal | Should be the appropriate size for the spot welds being drilled |

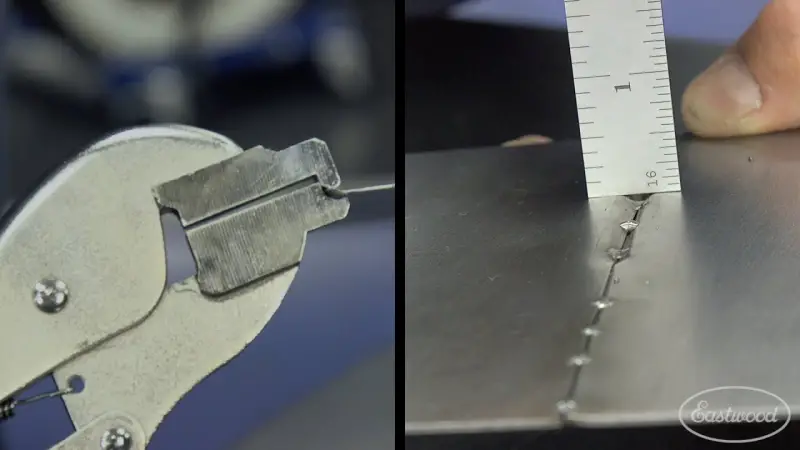

| Spot weld gun | To attach the new sheet metal using spot welds | Should be compatible with the size of the spot welds being used |

| MIG welder | To weld the sheet metal to the vehicle | Should be compatible with the type of metal being used for the repair |

| Protective gear | To protect the eyes and skin from sparks and debris | Should include safety glasses, gloves, and a welding helmet or mask |

Note: The specific equipment needed will depend on the type and size of the rust repair being performed, as well as personal preference and experience. This list is meant to serve as a general guide and may not include every tool needed for every repair.

Step-by-Step Instruction On What Gauge Sheet Metal For Rust Repair

- Determine the size of the repair area: Measure the length, width, and depth of the area that needs to be repaired, including any curves or contours.

- Determine the thickness of the existing sheet metal: Use a sheet metal gauge tool to measure the thickness of the existing sheet metal around the repair area.

- Choose the appropriate gauge of sheet metal: For rust repairs, it’s best to use sheet metal that is the same thickness as the existing sheet metal. If the existing sheet metal is too thin, the repair may not be strong enough. If it’s too thick, it may be difficult to bend and shape to fit the contours of the repair area.

- Cut the sheet metal to size: Use a metal cutting saw to cut the sheet metal to the appropriate size for the repair area. Be sure to leave a little extra sheet metal around the edges to allow for adjustments and trimming.

- Bend the sheet metal to fit the contours: Use a metal bending tool to bend the sheet metal to fit the curves and contours of the repair area. Make any necessary adjustments to the shape of the sheet metal until it fits perfectly.

- Create any necessary holes: Use a metal hole punch to create holes for screws or rivets as needed.

- Attach the sheet metal to the vehicle: Depending on the type of rust repair being performed, attach the sheet metal using rivets, spot welds, or welding. Make sure to follow all safety precautions, including wearing protective gear such as safety glasses and gloves.

- Check for proper fit and finish: Once the sheet metal is attached, check for proper fit and make any necessary adjustments. Trim any excess sheet metal and smooth any rough edges.

- Paint the repair area: Finally, paint the repair area to match the surrounding body of the vehicle.

Note: The specific steps and equipment needed will depend on the type and size of the rust repair being performed. This guide is meant to serve as a general outline and may not include every step required for every repair. It is always recommended to consult a professional or refer to a specialized repair manual for more specific and detailed instructions.

F.A.Q.

What is the best gauge of sheet metal to use for rust repair?

The best gauge of sheet metal to use for rust repair is the same thickness as the existing sheet metal around the repair area. If the existing sheet metal is too thin, the repair may not be strong enough. If it’s too thick, it may be difficult to bend and shape to fit the contours of the repair area.

Can I use a different gauge of sheet metal than the existing metal for rust repair?

While it is possible to use a different gauge of sheet metal for rust repair, it is recommended to use the same thickness as the existing metal for the best results. Using a different gauge may result in a repair that is not as strong or durable, or may not match the contours of the surrounding body.

How do I determine the thickness of the existing sheet metal?

To determine the thickness of the existing sheet metal, use a sheet metal gauge tool. Simply place the gauge over the metal and read the measurement.

How do I attach the new sheet metal to the vehicle for rust repair?

The method for attaching the new sheet metal to the vehicle will depend on the type of rust repair being performed. Common methods include rivets, spot welds, or welding.

Is it necessary to paint the repair area after attaching the new sheet metal?

Yes, it is recommended to paint the repair area after attaching the new sheet metal to match the surrounding body of the vehicle and protect it from further rust and corrosion.

Can I perform rust repair on my own or do I need to hire a professional?

Rust repair can be performed on your own if you have the proper tools and experience, but it can also be a complex and time-consuming process. If you’re not comfortable with the task, it’s best to consult a professional for assistance.

Leave a Reply