Bending aluminum posts can be a tricky task, but with the right tools and techniques, it can be done with ease. Aluminum is a versatile metal that is widely used in various applications due to its light weight and strength. However, bending aluminum requires a different approach compared to other metals, as aluminum has a tendency to crack or break if not handled correctly. In this guide, we’ll outline the steps to successfully bend aluminum posts and avoid any common mistakes.

To bend aluminum posts, you’ll need a few key tools, including a metal bender, aluminum stock, and a heat source. First, measure and mark the desired bend line on the aluminum post. Then, place the aluminum post in the metal bender, with the bend line aligned with the bending die. Next, heat the area around the bend line using a heat source, such as a propane torch or heating lamp. This will help to make the aluminum more pliable and easier to bend without cracking or breaking.

Finally, use the metal bender to apply pressure to the aluminum post, slowly bending it to the desired angle. Take your time and be patient during this process to ensure that the aluminum is bending evenly and without any cracks or breaks. After the bend has been made, let the aluminum post cool completely before removing it from the metal bender. Repeat the process for any additional bends that are required. With these simple steps, you’ll be able to bend aluminum posts with ease and achieve professional-looking results.

How To Bend Aluminum – Quick Overview

Bending aluminum is a fun and exciting process that can open up a whole new world of possibilities for your projects. Whether you’re working on a DIY project at home or fabricating parts for a business, bending aluminum is a great skill to have in your toolkit. And let me tell you, the results are so satisfying! The finished product is a beautifully curved piece of aluminum that you can be proud of.

So, what do you need to bend aluminum?

- First, you’ll need a metal bender. These come in a variety of shapes and sizes, so you’ll want to choose one that’s appropriate for the size of the aluminum pieces you’ll be bending. Some metal benders can handle small pieces, while others are designed for larger ones. Make sure to select the right tool for your project to ensure a smooth bending process.

- Next, you’ll need some aluminum stock. This is the raw material that you’ll be bending. Aluminum comes in a variety of shapes and sizes, so choose the one that’s best for your project. You can find aluminum stock at most hardware stores or online.

- Now that you have your tools and materials, it’s time to start bending! First, measure and mark the bend line on the aluminum stock. Then, place the aluminum in the metal bender with the bend line aligned with the bending die. To make the aluminum more pliable and easier to bend, you’ll need to heat the area around the bend line. This can be done using a propane torch or heating lamp.

- Finally, it’s time to bend! Slowly apply pressure to the aluminum using the metal bender. Take your time and be patient, as aluminum has a tendency to crack or break if not handled correctly. The key is to bend evenly and avoid applying too much pressure too quickly.

Once you’ve finished bending, let the aluminum cool completely before removing it from the metal bender. And that’s it! With these simple steps, you’ll be able to bend aluminum with ease and achieve beautiful, professional-looking results.

So what are you waiting for? Get out there and start bending aluminum today! I promise, you won’t regret it. The process is so much fun and the results are truly impressive.

Bending Aluminum Methods: Comparison Table

Bending aluminum is a process that can be accomplished using various permanent methods, each with its own unique set of tools, techniques, and results. Some of the most common methods include:

- Roll Bending: This is a process that uses three rolls to bend aluminum into a curved shape. Roll bending is a great option for large, flat pieces of aluminum, as it can create a smooth, consistent bend. The drawback of roll bending is that it can be time-consuming and requires specialized equipment, making it less suitable for small-scale projects.

- Brake Bending: This method uses a brake press to bend aluminum into a specific shape. Brake bending is a versatile option that can be used to create a wide range of shapes, including angles and curves. It is also faster and more efficient than roll bending, making it a popular choice for industrial applications.

- Hot Bending: This method uses heat to soften the aluminum, allowing it to be bent into a specific shape. Hot bending is a great option for creating tight curves and bends, as it allows for greater control over the final shape. However, hot bending requires specialized equipment and a high level of skill, making it less suitable for beginners or small-scale projects.

- Cold Bending: This method uses a metal bender to bend aluminum without the use of heat. Cold bending is a simple and straightforward method that is suitable for beginners and small-scale projects. However, cold bending can result in cracking or breaking if not performed correctly, and may not produce as smooth or consistent results as other methods.

Here is a comparison table of the different permanent methods for bending aluminum:

| Method | Advantages | Disadvantages | Suitable for |

|---|---|---|---|

| Roll Bending | Smooth, consistent bends | Time-consuming, requires specialized equipment | Large, flat pieces of aluminum |

| Brake Bending | Versatile, fast, efficient | Requires specialized equipment | Industrial applications |

| Hot Bending | Allows for tight curves and bends | Requires specialized equipment, high level of skill | Creating tight curves and bends |

| Cold Bending | Simple, straightforward | Can result in cracking or breaking, may not produce smooth results | Beginners, small-scale projects |

Each method has its own set of advantages and disadvantages, so it’s important to choose the one that’s best for your specific project. With the right tools and techniques, you can successfully bend aluminum and create beautiful, professional-looking results.

Equipment To Work With How To Bend Aluminum

| Equipment | Purpose |

|---|---|

| Metal Bender | Tool used to bend aluminum into a specific shape |

| Propane Torch or Heating Lamp | Used to heat the aluminum to make it more pliable and easier to bend |

| Roll Bending Machine | Three-roll machine used to bend large, flat pieces of aluminum |

| Brake Press | Used to bend aluminum using a brake press |

| Measuring Tape | Used to measure and mark the bend line on the aluminum |

| Aluminum Stock | Raw material used for bending |

| Safety Equipment (gloves, goggles, etc.) | Used to protect yourself while working with metal and heat sources |

Note: The specific equipment you’ll need will depend on the method you choose for bending aluminum. This table provides a general overview of the equipment you might need for different methods.

Step By Step Instruction On How To Bend Aluminum

- Choose your method: Choose the method that’s best for your specific project. Consider factors such as the size and shape of your aluminum stock, the type of bend you want to create, and the tools and equipment you have available.

- Prepare your aluminum: Clean your aluminum to remove any dirt, grease, or other contaminants that could affect the quality of your bend. Measure and mark the bend line on the aluminum using a measuring tape.

- Heat the aluminum (if using hot bending method): If you’re using the hot bending method, you’ll need to heat the aluminum to make it more pliable. You can do this using a propane torch or heating lamp. Be sure to wear safety equipment, such as gloves and goggles, to protect yourself while working with heat sources.

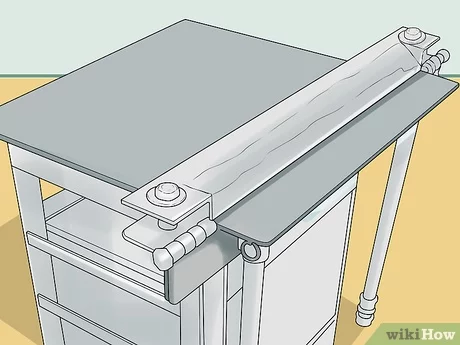

- Place the aluminum in the bender: Depending on the method you’ve chosen, you may need to place the aluminum in a roll bending machine or brake press. Make sure the aluminum is properly aligned and secure before starting the bend.

- Apply pressure to the aluminum: Use the bender to apply pressure to the aluminum, bending it into the desired shape. If you’re using the hot bending method, you may need to apply pressure while the aluminum is still hot. If you’re using the cold bending method, you may need to apply pressure in a slow and steady manner to avoid cracking or breaking the aluminum.

- Check the bend for accuracy: After bending the aluminum, inspect it for accuracy and make any necessary adjustments. If you’re using the hot bending method, be sure to allow the aluminum to cool completely before making any adjustments.

- Repeat the process: Repeat the process as needed until you’ve bent all the aluminum pieces you need for your project.

Note: The specific steps you’ll need to follow will depend on the method you choose for bending aluminum. This guide provides a general overview of the steps involved in the process.

With these steps, you’ll be able to successfully bend aluminum and create beautiful, professional-looking results. Just be sure to take your time and follow all safety precautions, and you’ll be well on your way to a successful project.

F.A.Q.

What are the different methods for bending aluminum?

There are two main methods for bending aluminum: hot bending and cold bending. Hot bending involves heating the aluminum to make it more pliable, while cold bending involves applying pressure to the aluminum without heating it. The method you choose will depend on factors such as the size and shape of your aluminum stock, the type of bend you want to create, and the tools and equipment you have available.

Can aluminum be bent without cracking or breaking?

Yes, aluminum can be bent without cracking or breaking if the proper techniques are used. For example, when using the cold bending method, it’s important to apply pressure in a slow and steady manner to avoid cracking or breaking the aluminum. When using the hot bending method, it’s important to heat the aluminum evenly and to allow it to cool completely before making any adjustments.

Is it necessary to clean the aluminum before bending it?

Yes, it’s necessary to clean the aluminum before bending it to remove any dirt, grease, or other contaminants that could affect the quality of your bend.

Can a metal bender be used to bend aluminum?

Yes, a metal bender can be used to bend aluminum, but it’s important to choose the right metal bender for the job. Some metal benders are designed specifically for bending aluminum, while others are more versatile and can be used to bend a variety of metals.

What safety equipment should I use when bending aluminum?

It’s important to wear safety equipment, such as gloves and goggles, when working with aluminum and heat sources. This will help to protect you from any potential hazards.

Leave a Reply