Galvanizing is a process that coats metal with zinc. This is done to protect the metal from corrosion and rust. The most common use for galvanized metal is in roofing and siding.

What Does Galvanized Metal Mean?

The word galvanize can mean two things. The first is to coat metal with zinc in order to protect it from corrosion and rust. The second is to stimulate or excite someone into action. In the case of galvanized metal, we are talking about the former definition.

Galvanizing metal is a process where zinc is applied to steel or iron in order to form a protective layer on its surface. This process is also known as hot-dip galvanization. The zinc layer helps to prevent corrosion of the metal and protects it from rusting.

How does Galvanization Work?

Galvanization works by forming a barrier between the metal and the environment. The zinc coatingsacrifices itself to protect the steel or iron beneath it. When the zinc coating is damaged, it will corrode before the steel or iron does.

This process is an effective way to protect metals from corrosion and rust. It is often used on roofing and siding because these materials are exposed to the elements. Galvanized metal can also be found in gutters, pipes, and other construction applications.

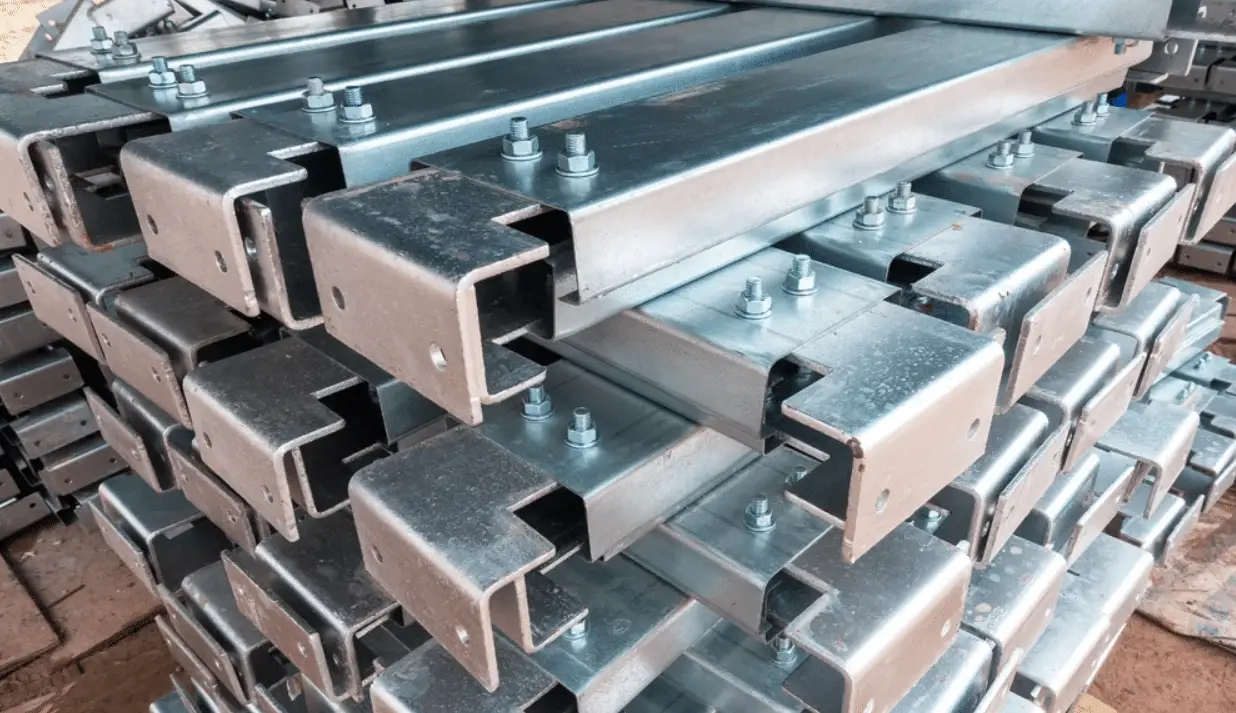

Galvanized Steel Product Options

There are a few different types of galvanized steel products on the market. The most common is hot-dip galvanized steel. This type of steel is dipped into molten zinc in order to form a protective coating.

Another option is electro-galvanized steel. This type of steel is coated with zinc through an electrolytic process. It is not as effective as hot-dip galvanization, but it can be used for applications where corrosion is not a major concern.

The third type of galvanized steel is pre-galvanized steel. This type of steel has been coated with zinc at the mill before it is sold. It is ready to use when it arrives at the job site and does not require any additional galvanization.

Galvanized steel is an effective way to protect metal from corrosion and rust. It is available in a variety of product options to meet the needs of any application.

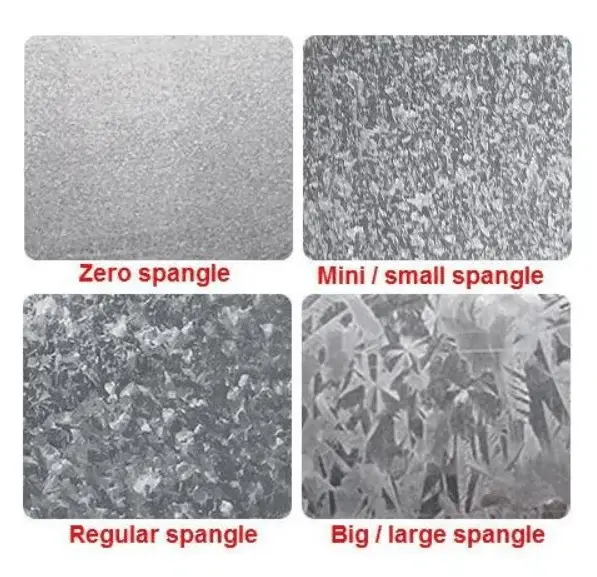

Spangle in Galvanized Steel

One of the most common questions about galvanized steel is what is spangle? Spangle is the zinc crystals that form on the surface of the steel during the galvanizing process.

These crystals can be large or small, and they can be distributed evenly or unevenly on the surface of the metal. The type of spangle that forms on the surface of the steel will depend on the conditions during galvanization.

The three most common types of spangle are regular, minimum, and zero. Regular spangle is the most common type of spangle. It forms when the zinc crystalizes in a random pattern on the surface of the steel. Minimum spangle forms when there is a low level of zinc in the molten bath.

Spangle Variations

Zero spangle is the desired result for many applications. This type of spangle forms when there is no zinc crystalization on the surface of the steel. The steel is passed through a chromate bath after galvanization to remove any remaining zinc crystals.

There are a few other types of spangle that can form on the surface of galvanized steel. These include mottle, dendrite, and blister. Mottle is a random pattern of small and large zinc crystals. Dendrite is a branching pattern of zinc crystals.

Blister is a raised area on the surface of the steel that contains zinc crystals. These variations are not as common as regular, minimum, or zero spangle.

Spangle is the zinc crystals that form on the surface of galvanized steel during the galvanizing process. The type of spangle that forms will depend on the conditions during galvanization. regular, minimum, and zero spangle are the most common types.

Advantages of Galvanized Steel

Galvanized steel is a popular choice for many applications because of its low cost, durability, and easy maintenance.

Galvanized steel is also easy to clean and can be painted if desired. The low maintenance requirements make it a good choice for gutters, pipes, and other construction applications.

Galvanized steel is an affordable option that is durable and easy to maintain. It is a good choice for many applications, both indoors and out.

Disadvantages of Galvanized Steel

Galvanized steel does have a few disadvantages. The most common is that it can be difficult to weld. Galvanized steel emits toxic fumes when heated, so special precautions must be taken when welding.

Another disadvantage of galvanized steel is that it is not as corrosion resistant as other options, such as stainless steel.

Applications for Galvanized Steel

Galvanized steel is commonly used in construction applications, such as gutters, pipes, and roofing. It is also a popular choice for fences, sheds, and storage containers.

Galvanized steel is an affordable option that is durable and easy to maintain. It is a good choice for many applications, both indoors and out.

When choosing galvanized steel for your next project, keep in mind the advantages and disadvantages of this popular material.

Does Galvanized Steel Rust?

Galvanized steel is less likely to rust than other types of steel. The zinc coating protects the steel from corrosion and rust, and it is often used in construction applications, such as gutters, pipes, and roofing.

However, galvanized steel is not entirely rust-proof. The zinc coating can be damaged over time, exposing the steel to corrosion and rust.

Galvanized steel is a popular choice for many applications because it is affordable and durable. However, it is not completely rust-proof.

When choosing galvanized steel for your next project, keep in mind that it may eventually rust.

Galvanized Steel Maintenance

Galvanized steel does require some maintenance to prevent rust. The best way to prevent rust is to keep the steel clean and dry.

If the steel does become wet, it should be dried as soon as possible to prevent corrosion.

When choosing galvanized steel for your next project, keep in mind that it will require some upkeep to prevent rusting.

What is galvanized metal coated with?

Galvanized metal is coated with zinc to protect it from corrosion and rust. The zinc coating also makes it easier to clean and paint if desired. Galvanized steel is a popular choice for many applications because of its low cost, durability, and easy maintenance.

What is the best primer for galvanized metal?

The best primer for galvanized metal is one that is made specifically for this purpose. There are many brands and types of primer available, so it is important to read the labels carefully to choose the right one.

Be sure to follow the directions on the label when applying primer to galvanized metal.

What is the difference between galvanized and galvalume?

Galvanized steel is coated with zinc to protect it from corrosion and rust. Galvalume is a type of steel that is coated with aluminum-zinc alloy. This coating provides better protection against corrosion and rust than zinc alone.

What is the best paint for galvanized metal?

The best paint for galvanized metal is one that is made specifically for this purpose. There are many brands and types of paint available, so it is important to read the labels carefully to choose the right one.

We recommend POR-15 Gloss Black Top Coat Paint –32 fl oz – Direct to Metal Paint for Galvanized and Bare Metal Surfaces. POR-15 Top Coat is essential for that extra layer of durability and provides optimum protection against UV light that won’t fade over long-term exposure.

This paint is designed specifically for galvanized metal, and it will provide a high-gloss finish that is durable and long-lasting.

POR-15 Top coat has exceptional long-term sheen and color retention, with a hammer tough finish that won’t crack or peel. It can be applied directly to metal substrates or previously painted surfaces without the need for primer or undercoat. Formulated to form a robust barrier that sheds moisture.

How to Apply

All surfaces must be clean and free of all dirt, loose rust, oil, grease, wax, soap, loose paint & any other matter. Use 25-30 lbs (170Kpa-210pa) pressure for normal gloss. It dries to touch in 30-60 minutes. POR-15 Top Coat can take 3-4 days to reach maximum hardness, and longer in temperatures below 55°F (15°C).

How do you tell if a metal is galvanized?

Galvanized metal has a dull, silver-gray finish. It is sometimes mistaken for stainless steel. Stainless steel has a shiny, lustrous finish and is more resistant to corrosion than galvanized metal.

To test if a metal is galvanized, apply a small amount of vinegar to the surface with a cotton swab. If the metal is galvanized, the vinegar will react with the zinc and create a bubbling effect.

If there is no reaction, the metal is most likely stainless steel.

How long does galvanized steel last?

Galvanized steel can last for decades if properly maintained. The zinc coating protects the steel from corrosion and rust, but it can be damaged over time.

It is important to regularly inspect galvanized steel for signs of wear and tear. If the coating is damaged, it will need to be repaired or replaced to prevent rust and corrosion.

Can Galvanised steel rust?

No, as it will rust only if damaged. Galvanized steel is designed to resist rust and corrosion, but it is not completely impervious to these elements. Over time, the zinc coating can be damaged by exposure to the atmosphere, making the steel vulnerable to rust and corrosion.

It is important to regularly inspect galvanized steel for signs of wear and tear. If the coating is damaged, it will need to be repaired or replaced to prevent rust and corrosion.

What is galvanized metal good for?

Galvanized metal is most often used in outdoor applications because of its ability to resist corrosion and rust. It is also used in the automotive industry for car bodies, engine blocks, and exhaust systems.

Galvanized steel is also often used in the construction of buildings and bridges. The zinc coating protects the steel from corrosion and rust, making it a durable and long-lasting material.

What is considered galvanized metal?

Galvanized metal is any steel that has been coated with a layer of zinc. This process is known as galvanization and protects the steel from corrosion and rust.

Overall

Galvanized metal is a type of steel that has been coated with zinc to protect it from corrosion and rust. It is most often used in outdoor applications because of its durability, and it can also be found in the automotive, construction, and building industries. Galvanized metal is considered a reliable material for resisting rust and corrosion.

Very informative article.