Rusted metal is a common problem faced by many individuals and industries alike, but did you know that this seemingly useless material can actually be recycled? Yes, that’s right! Rust may seem like a hindrance, but it doesn’t necessarily mean that the metal is beyond repair. In fact, with the right recycling process, rusted metal can be transformed into a valuable resource that can be reused in a variety of ways.

The recycling of rusted metal involves removing the rust and then melting the metal down to its core form. The melted metal is then poured into molds to create new products, or it can be used as raw material for other manufacturing processes. The steel obtained from recycled rusted metal can be used in the production of automobiles, construction materials, household appliances, and a wide range of other products. In this way, recycling rusted metal not only reduces the amount of waste in landfills, but it also conserves natural resources by reducing the need to extract new materials from the earth.

The recycling of rusted metal is not only environmentally friendly, but it is also economically advantageous. The recycling process not only saves on the cost of extraction and refining of new materials, but it also saves on the energy needed to produce new metal. In addition, the recycling of rusted metal reduces the demand for new metal, which can help to stabilize metal prices and make metal products more affordable for consumers.

Can Rusted Metal Be Recycled Overview

Let me tell you a little about the process of recycling rusted metal. The first step is to remove the rust, which can be done through various methods such as sandblasting, abrasive blasting, or chemical treatments. Once the rust is removed, the metal is melted down to its core form and transformed into new products. This melted metal can be used to create new steel products such as construction materials, automobiles, household appliances, and more.

One of the things I love about the recycling of rusted metal is the environmental impact it has. Not only does it reduce the amount of waste in landfills, but it also conserves natural resources by reducing the need to extract new materials from the earth. It’s amazing to think about how we can create new products while also being environmentally responsible.

Another advantage of recycling rusted metal is the economic benefits. The cost of extracting and refining new materials can be high, and recycling rusted metal saves on those costs. In addition, the energy required to produce new metal is also reduced. This not only helps to make metal products more affordable for consumers, but it also stabilizes metal prices.

In conclusion, the recycling of rusted metal is a fantastic solution to a common problem. The process is environmentally friendly, economically advantageous, and it produces valuable products that can be used in a variety of applications. I’m so excited about the possibilities that come with recycling rusted metal and I can’t wait to see how it continues to evolve and grow in the future.

Can Rusted Metal Be Recycled: In Comparison

- Metal: The metal used in the recycling process can vary, but the most common type is steel. Steel is a popular choice due to its durability, versatility, and recyclability. Other metals that can be recycled include iron, aluminum, and copper.

- Rust: Rust is formed when metal is exposed to oxygen and moisture, causing the metal to corrode and deteriorate over time. When recycling rusted metal, the rust must be removed in order to access the metal underneath.

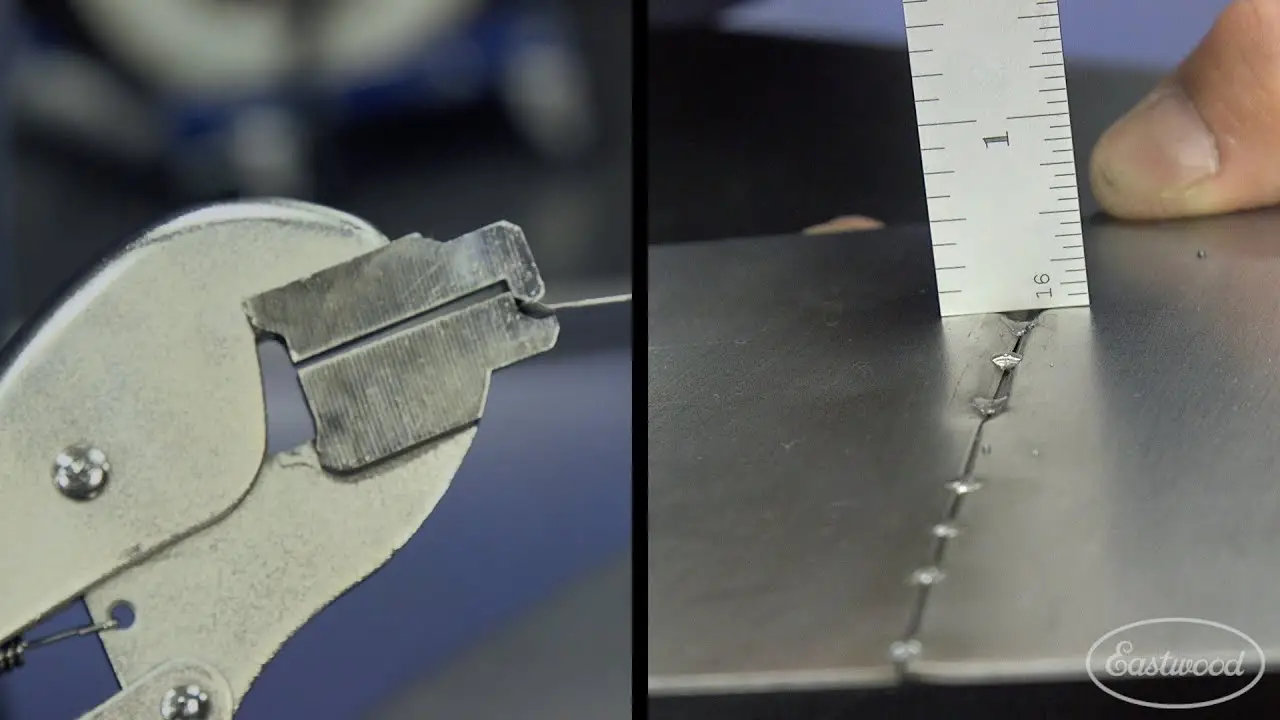

- Rust Removal Methods: There are several methods that can be used to remove rust, including sandblasting, abrasive blasting, and chemical treatments. Each method has its own advantages and disadvantages, and the choice of method will depend on the type of metal and the extent of the rust.

Here is a comparison table of the different rust removal methods:

| Method | Advantages | Disadvantages |

|---|---|---|

| Sandblasting | Fast and efficient | Can produce hazardous dust |

| Abrasive blasting | Effective for removing heavy rust | Can damage the metal surface |

| Chemical treatments | Non-abrasive, gentle on the metal surface | Can be time-consuming and requires careful handling |

In conclusion, these are the key ingredients involved in the recycling of rusted metal. Each of these components plays an important role in the process and their choice will depend on various factors such as the type of metal, the extent of the rust, and the desired outcome.

Equipment To Work With Rusted Metal

When working with rusted metal, there are several pieces of equipment that are necessary to ensure a successful recycling process. The following table lists some of the most common pieces of equipment used in the recycling of rusted metal:

| Equipment | Purpose |

|---|---|

| Blast cabinet | Used to remove rust through sandblasting or abrasive blasting |

| Chemical tanks | Used to treat the metal with chemicals for rust removal |

| Protective gear | Safety equipment such as gloves, masks, and eye protection |

| Furnace | Used to melt down the metal to its core form |

| Molds | Used to shape the melted metal into new products |

| Safety equipment | Equipment to ensure the safety of the operator, such as fire extinguishers and first aid kits |

In addition to these pieces of equipment, various tools and machinery may also be required depending on the type of metal and the desired outcome. For example, metalworking equipment such as lathes and presses may be used to shape and refine the recycled metal.

It’s important to note that the equipment used in the recycling of rusted metal will vary depending on the size of the operation and the desired outcome. However, the above table lists some of the most common pieces of equipment used in the recycling process.

Step By Step Instruction on How to Recycle Rusted Metal

- Collect the rusted metal: The first step is to gather the rusted metal, which can be obtained from sources such as scrap yards, construction sites, or decommissioned machinery.

- Sort the metal: Once you have collected the rusted metal, it’s important to sort it by type and size. This will make it easier to process and ensure that you are recycling the most appropriate types of metal.

- Remove the rust: The next step is to remove the rust from the metal. This can be done through various methods such as sandblasting, abrasive blasting, or chemical treatments. The choice of method will depend on the type of metal and the extent of the rust.

- Melt the metal: Once the rust has been removed, the metal is ready to be melted down to its core form. This can be done in a furnace and the melted metal is then poured into molds to create new products.

- Refine the metal: After the metal has been melted, it may need to be refined and shaped into the desired form. This can be done using metalworking tools and machinery, such as lathes and presses.

- Final product: Once the metal has been shaped into its final form, it is ready to be used in a variety of applications. This can include products such as construction materials, automobiles, household appliances, and more.

It’s important to note that the specific steps involved in the recycling of rusted metal may vary depending on the type of metal, the extent of the rust, and the desired outcome. However, the above steps provide a general overview of the process.

F.A.Q.

Can all types of metal be recycled?

Not all types of metal can be recycled, but many can. The most commonly recycled metals include steel, iron, aluminum, and copper.

Is rust harmful to the environment?

Rust itself is not harmful to the environment, but if not properly handled, the chemicals used in rust removal can be harmful. It is important to follow proper safety procedures and guidelines when recycling rusted metal.

What is the most efficient method for removing rust?

The most efficient method for removing rust will depend on the type of metal and the extent of the rust. Popular methods include sandblasting, abrasive blasting, and chemical treatments.

Can recycled metal be used in high-stress applications?

Yes, recycled metal can be used in high-stress applications, such as construction materials and automobiles, provided that it has been properly processed and refined.

Is recycling rusted metal profitable?

Yes, recycling rusted metal can be profitable as the price of metal can vary depending on the market demand. In addition, recycling saves energy and resources compared to producing new metal.

Is it safe to work with rusted metal?

Yes, it is safe to work with rusted metal if proper safety procedures and equipment are used. This includes wearing protective gear such as gloves, masks, and eye protection, as well as following guidelines for safe handling of chemicals and other hazardous materials.

Leave a Reply